English version » Properties

« backMr.Teks® screws characteristics

What is the Mr.Teks®?

Mr.Teks® is a marking for self-drilling screws, which are made of the special Cr-Mo-Ni stainless steel of martensitic type, partially corresponding with X30CrMo13–2 steel. The given alloying system containing 13 – 14,5% of Cr provides not only strong resistance against corrosion comparable with A2 steels, but also an excellent combination of mechanical characteristics (48 – 51 HRC and Rm = 640 – 670 N/mm2). The screws Mr.Teks® are suitable for joining steel, aluminium and thin stainless sheets.

What is a stainless steel of martensitic type?

Contrary to austenitic stainless steels (e.g. A2 or A4) which basic microstructural element is an austenite (paramagnetic γ-phase with a cubical, face-centered elementary grid) the final microstructure of martensitic steels is created by a martensite (a ferromagnetic α-phase with a cubical spatially-centered elementary grid) which is a product of hardening. It is impossible to harden the austenitic steels therefore the characteristics at the level of harden-able steels cannot be reached. This is a general distinction between both types. They are equal only from the aspect of resistance against corrosion.

The advantages of Mr.Teks® screws

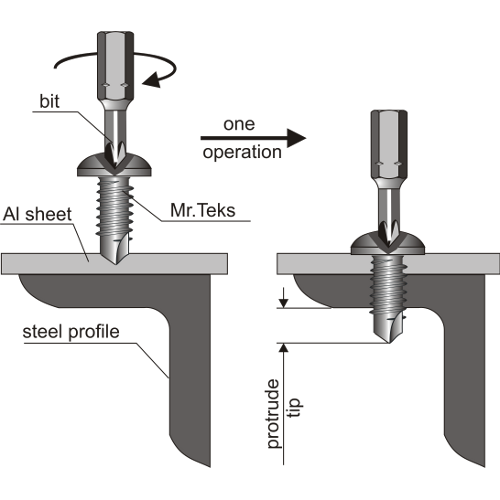

- costs savings because of an inlet pre-drilling operation absence

- no problems with reseating the inlets

- nut-free, clearance-free bolted joint

- simple logistics and rational assembly

- strong resistance against corrosion

Example of use:

Construction recommendation

- hardness of joined material max. 125 HV (Rm = max. 420 N/mm2)

- overall sheets thickness have to be higher than lead angle

- it is necessary to take into consideration the appearance of chips when drilling and the danger of injury caused by protruded screw tip

- the recommended revolutions are:

- for d1 = 2,9 – 4,8: 1500 up to 2500 revs/min

- for d1 = 5,5 – 6,3: 1200 up to 1800 revs/min

- before serial assembly it is recommended to realise tests and select optimal tightening moment.

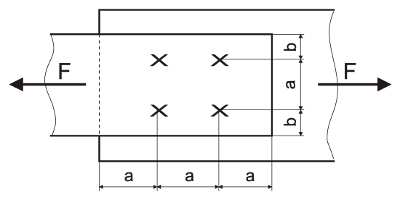

- the recommended arrangement of screws at tensile loading of patched sheet is shown in the figure below

amin = 3d, bmin = 1.5d, d is a screw diameter and F is a tensile power